Living in Australia....

...has a whole load of advantages, but one thing that sucks is that we are far from everyone else. So once I've ordered my parts, I have to wait a while for the bits to arrive.

And that usually gets me thinking. Well, reading articles on the internet is kind of like thinking....

DAMN FINE DIY

There are some pretty talented and smart people out there, and I've recently read about some examples of DIY Solder Paste stencils. Both of these guys have achieved some pretty impressive results, and with my upcoming projects, I started to think that the use of solder stencils might just save me some time.

While I can hand solder SMD parts, and when set up I've been able to knock off over 100 parts an hour, it's bloody fatiguing. Plus I have this hot air tool I picked up from eBay that I haven't tried yet either... so I began to hatch a plan.

However, rather than muck around with etching and all the drama that comes with using chemicals (e.g. negative WAF) I thought I'd give it a shot milling out a stencil at work.

LUNCH TIME ATTACK

So one lunch time, I took to a Red Bull can with a pair of scissors, and turned it into a flat sheet. I grabbed a Gerber of the solder paste layer, threw it into the standard CircutiCAM profile, and gave it a quick shot in the mill.

The good news - the mill made nice clean cuts in the can (after tweaking the depth setting) and it all looked pretty promising. With the following photos, as you can see, it's hard to take a decent pic of shiny aluminium, but hopefully they are good enough for you to get the idea.

First Attempt - Cutting Side

First Attempt - Paste Side

As the cutter in the mill is a 0.2mm V-grove, I cut from the side that will be placed against the PCB (I cut the mirrored image). This, I reckoned, would compensate for the fact that the sides of the holes cut by the mill are not parallel, but tapered (due to the profile of the cutter). This leaves the largest part of the hole on the board face and when solder paste is applied, and the stencil removed, I won't be pulling up excess paste.

This first attempt was basically to get it straight in my mind that it is possible to mill an aluminium can in a useful way - but not using the mills standard settings it seems.

Break through

As you can see in the above picture, the holes for the pads have been milled with very little clearance, and in some cases have broken through. It would have been unwise to attempt to use this as a stencil, as it will probably deposit too much solder paste and the excess will probably lead to bridged pads etc.

Close Up

TAKING MY TIME TO GET IT RIGHT

I had a look at the CircuitCAM files and settings, and when milling a PCB the pats are set outside the pads and traces. Which makes sense in the case of making a PCB.

To get the solder paste stencil pads to match those of the PCB, I set the solder paste expansion rule in Altium to -0.1mm - half the cutter's diameter - and then bought this paste Gerber into CircuitCAM. I then set all 'insulate' settings to zero, and recalculated the cutter paths.

CircuitCAM Defaults

In the above pic, the green lines illustrate the cutter path. You cam see that there are actually two paths around each pad - this is to give a decent insulation barrier between conductors when milling a board. But this is why my above attempt failed.

Single Cutter Paths

Outline Pads

From the two pics above, you can see that there is now only one cutter path, (second pic has pads shown as outlines for clarity) and after processing and milling I was pretty happy with the result!

Pads with No Breakthrough!

Back Lit

Again, I milled the mirror image, but I milled from the blank side - meaning that the can's artwork will be facing me when used as a stencil. D'oh.

Distracting, but Lined up.

With the can's artwork facing you, it's hard to see the alignment with the PCB underneath it - but you can make it out. Above shows the pads of the pcb peaking through the stencil. Win!

MORE ON JIGS

It's one thing to have a stencil, it's another to line it up with PCBs and actually use it. When you need to line stuff up, I've found it worth the effort to produce a jig to make life easier.

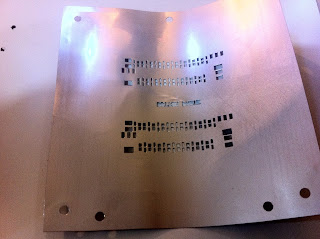

Base Plate

To start with, I milled out a base plate - the plan is to use alignment holes that are to take tooling pins to help line up further layers of the jig. However I only have the one of these to hand at the moment so I have to wait until I have more to finish the jig. These pins are 3mm diameter, and made from hardened steel. The base plate is made from Masonite.

The scratches across the face of the Masonite are due to me being in a hurry - I don't think I had it fitted dead flat in the mill and the cutting bit was dragged across it's surface. But m'eh, it's only cosmetic and doesn't stop it from working. You might also see that the pins are not symmetrical around both x and y axes - this is to help with aligning the stencil.

It fits!

For the base plate, the pin is actually an interference fit. This means you can tap the pins into place and they stay put. Woot.

Cutting Out

Board Holder

The above shows the board holder - I plan on putting an FR4 board underneath it as the Masonite doesn't have a hard wearing surface. You may be thinking that this is overkill - and if I were to use this jig for just one PCB design it would be - but my plan here is to reuse this jig with multiple designs - it's built big enough to accommodate 10x10cm PCB's. All I have to do is swap the board holder and stencil and I'm good to go.

You'll notice that there are engraving marks on the board holder - this is because I used this sheet as a backing plate to the can when making the stencil. No waste around here buddy!

Boards Fitted

Next is the stencil. At this point I was a concerned that the can was too thin at only 0.1mm thick (as measured with my el-cheapo verniers). Rummaging around I found some plastic sheet that measured 0.25mm thick and whipped up a stencil on the mill. As the CAD was all ready prepared this was literally done in under 10 minutes. Yay automation!

Stencil Comparisons

From left to right is the 2nd tin can stencil, the plastic and the reject first tin can stencil.

Plastic Stencil and Clamp

Once a stencil is fitted, I drop a clamping ring over the top. With the plastic stencil I don't think this is really needed as it sits nice and flat, but even though I had a basic attempt to flatten the can it's still got a bit of a bend in the sheet and the clamp eliminates it.

Tin Can Stencil Fitted

I've used 7 holes around the perimeter of the clamp. The plan here is screw the stencil in place (with M3 hardware) in the 4 corners, and the glue the stencil tho the frame. Then I can remove the screws and use three tooling pins as guide when building boards. I'll post about this as soon as I get around to it.

Plastic Fantastic

To get a better idea of the capability of the mill I've included the above close up of the plastic stencil. The outlines of the holes are quite visible and you can see how they compare with the pads of the target board underneath. The registration isn't too flash as I've not bothered to put too much effort into lining these up at the moment as I'm waiting on the pins to do it for me :)

As soon as the parts arrive, I'll give the paste and hot air a shot and let you know how I go - one way or the other.

A QUICK NOTE ON THICKNESS

In the interim I've been reading up on stencil thickness and I'm surprised at how thin some peoples stencils are - Kaptpon films at 0.003" for instance. Sunstone Circuits have a handy little stencil calculator, and from this I think the tin can is going to be fine. I'll probably only try the plastic stencil *if* the tin can fails.

Tip: before you drink the can you are using use super fine sandpaper to clean up the outside of the can. It helps if the can is carbonated/full.

ReplyDeleteHow did you fit the aliminum sheet to the milling table?

ReplyDeleterpm?

feed rate?